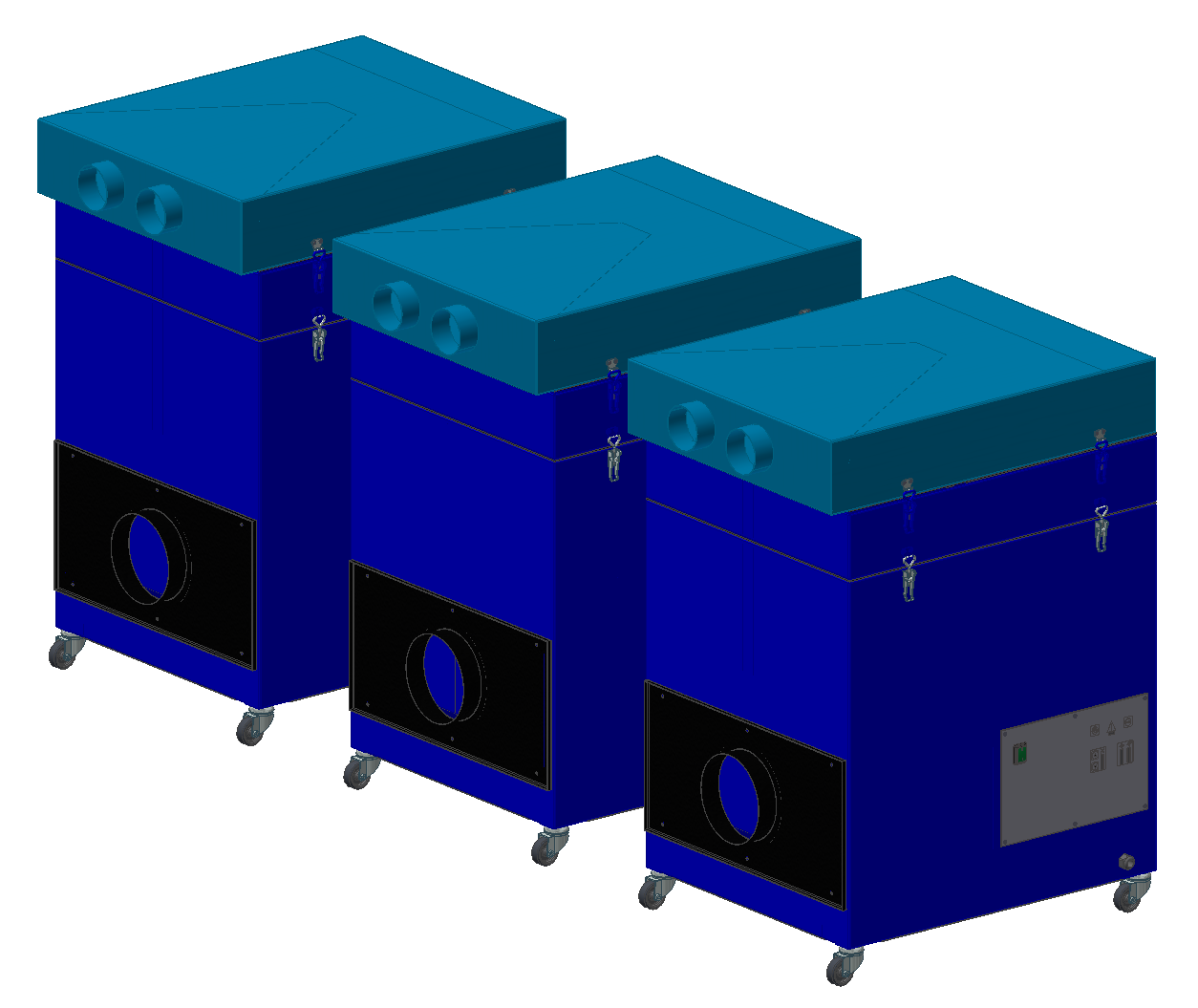

Extraction devices on a cleaning system

The important thing is that nothing comes out ... apart from clean air

Once in the filter, always in the filter

No matter how tiny something in the filter is, it stays in the filter

It will not let us down. The extraction and filtering devices from Fuchs Umwelttechnik meet the highest requirements for the collection and cleaning of even the slightest air pollutants every time they are switched on, for protection of man and machine.

The engineers at Fuchs Umwelttechnik combat the problems of extra fine particles with this new special development: Removal of residues from parts on a cleaning system by means of solvents such as acetone causes extra fine dusts. Microscopically small with just 50 nm, these are also highly carcinogenic.

The solution: An extraction stream collects all microscopic particles and feeds them into the filtering system during the entire machining process. The filtering system consists of three identical IKF0950.1 devices in which the hazardous substances are filtered out completely by several stages. In addition, an activated carbon filter absorbs any gas emissions. All the devices are connected to each other by an interface and are controlled centrally. A gas and a dust sensor additionally monitor the exhaust air stream.

No matter what is in the filter, it stays in the filter No compromise safety also when changing the filter: In the interests of comprehensive staff safety, special filter systems have been developed with a design that ensures contamination-free changing of saturated filters even under unfavourable conditions.

With this new extraction and filtering system from Fuchs Umwelttechnik, the user gets indispensable complete protection both during operation and during maintenance.

Technical data IKF950.1 (3x):

- Extraction volume max. free-blowing: 1,200 - 2,850 m³/h

- Max. stat. pressing: 5,000 Pa

- Rated voltage: 400 V

- Rated power: 3 x 1.4 kW

- Device dimensions (1 device)

- LxWxH in mm approx. 800 x 560 x 1,000

- 3 filter stages Pre-filter M5, floating particle filter H13/H14, gas filter (activated carbon)

Fuchs Umwelttechnik is further expanding its presence in Asia: With immediate effect, the company DBAY/NUOSUN, Shanghai is exclusively taking over sales of the complete product portfolio of extraction and filtering units from Fuchs Umwelttechnik in the Asian area.

Based on the now three-year cooperation between Fuchs Umwelttechnik and DBAY/NUOSUN, this sales partnership is uniting technical know-how with direct proximity to the market. Our customers in Asia will benefit, in future, from a direct local contact who can react expediently to all matters with well-founded consultation and fast, top-class service.

DBAY/NUOSUN stands for quality, reliability and technical expertise – ideal conditions for optimum representation of the advantages and performance capabilities of our extraction and filtering units on the Asian market. As of 01-03-2026, your inquiries and orders can be handled directly through DBAY/NUOSUN SHANGHAI.

We look forward to a continuing successful partnership and are certain that this cooperation will help to simplify processes and further optimise important procedures. DBAY/NUOSUN and Fuchs Umwelttechnik – as strong partners for the future!

The conversion unit was developed at the request of a customer who is already equipped with numerous TKFVA devices. For their sensor production, they required additional safety measures against the reactive dusts of CrNi steels and titanium. Since the INRVABE3.1 powdering module is designed exclusively for the higher emission quantities of the MKFVA and INRV device types, the consequence would be an expensive total replacement of the extraction and filtering units. Economically, this is no option and not at all what we have in mind.

To meet our customers' requirements, our engineers therefore designed the TKFVAÜG6 conversion unit especially for the appropriate performance data of the most compact device series with automatic filter cleaning TKFVA. With this, the INRVABE3.1 powdering module can now also be used for smaller emission quantities.

Sophisticated in every detail:

- Constant discharge through a chute into a 20-litre barrel by optimum positioning to the TKFVA, even during operation

- The powdering has been parametrised exactly for the smaller emission quantities

- A pinch valve is no longer required for the activation

- PE-film in the barrel for contamination-free disposal

- Barrel emptying by a quick clamp offline

With the new TKFVAÜG6 conversion unit, our customers now have a complete safety solution especially for smaller emission quantities at their disposal which can easily be integrated into existing systems.

Great interest in the TKFVA300 and cyclone pre-separator

The Pantron/Fuchs Umwelttechnik fair booth was a magnet for the professional visitors. Special focus was placed on our latest new developments: the compact TKFVA300 extraction and filtering unit and the cyclone pre-separator. Both systems were convincing in their technical design, their high quality, and their practical possibilities for use in many different industrial applications.

Many concrete customer inquiries from the region

Numerous companies in North and South Carolina took the opportunity to find out about tailor-made extraction and filtering solutions for their specific applications with concrete inquiries on site. Further appointments to visit the companies were arranged during the fair – a clear indication of the great interest in the performance capabilities of our extraction and filtering systems.

Outlook for the Southtec 2027

Following this successful fair appearance, Pantron and Fuchs Umwelttechnik would like to thank all visitors for their keen interest. The joint team is already looking forward to the Southtec 2027.