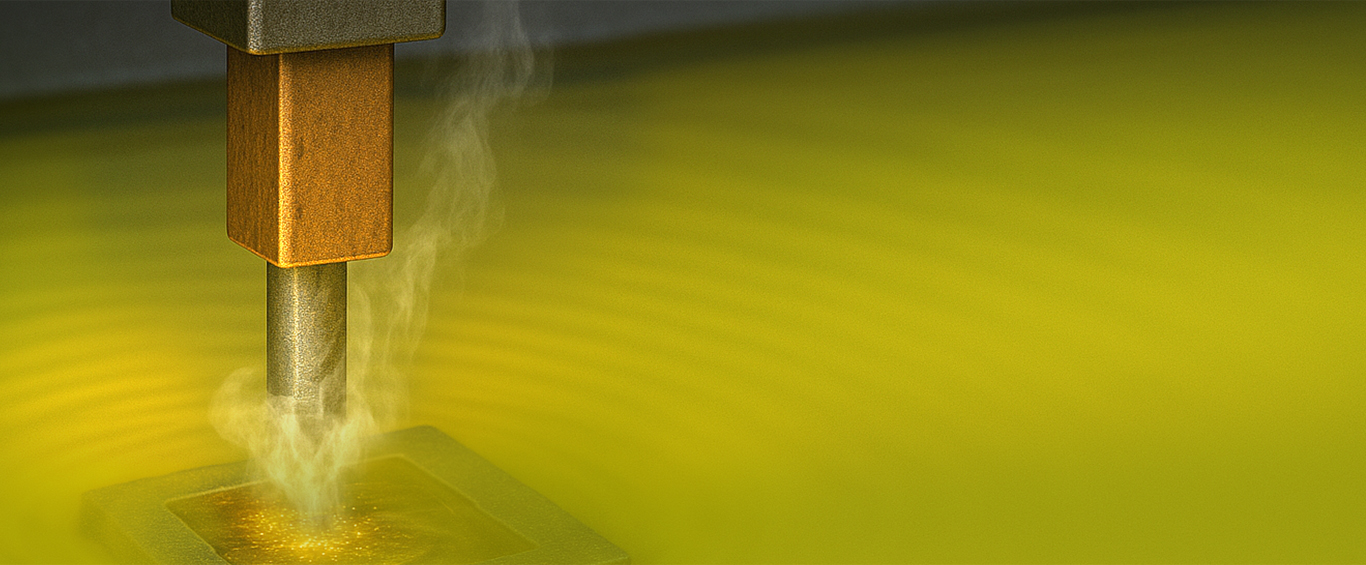

Eroding mist extraction

Tailor-made extraction and filtering units against aerosols

A medium-sized automotive parts manufacturer contacted Fuchs Umwelttechnik for a consultation appointment:

The initial situation:

The task:

Due to the high degree of material removal, large emission quantities occur which can only be eliminated completely with the appropriate separation factors. The limit values (MAC) of the materials can often be within the critical range. Handling of electrical voltage additionally presents the risk of explosion so that the explosion limits also need to be considered in the planning.

- High emission quantities demand high separation factors of the filters.

- The limit values (MAC) of the materials are often critical.

- Explosion limits (LEL = lower explosive limit of the materials according to the ATEX directive) must be observed as well as the appropriate fire safety measures.

Competent engineering consulting:

- In order to find the best solution for eroding mist extraction, the first talks take place directly between the customer and a specialist engineer from Fuchs Umwelttechnik.

- Project planning: The analysis of all customer requirements as well as the existing working and space conditions are the prerequisites for the tailor-made extraction system.

- Examination of the exact emission quantities and the optimum capture parameters are indispensable for our engineers for developing the most suitable application.

The solution:

Based on the information acquired from the customer, the engineers from Fuchs Umwelttechnik design the perfectly adapted extraction solution: Specifically aimed at the eroding machine, the specially adapted capture, the efficient transport and the corresponding extraction and filtering unit integrate smoothly into the existing system.

Multi-stage filter technologies are used, adapted to the bath size of the vertical eroding machine, the high pollutant quantities and the corresponding MAC limits. Larger particle concentrations are pre-separated by large metal mesh filters and expansion stages. HEPA filters are used for extremely fine aerosols. Activated carbon looks after solvent residues and minimises odour pollution.

In detail:

- Complete capture: Direct extraction and the special flow control of the extraction unit ensure direct capture of all vapours.

- Pre-separation: Large metal mesh filters and expansion stages for pre-separation of larger concentrations.

- Multi-stage filtering: Multi-stage filter technologies in the filtering unit eliminate the large pollutant quantities, adapted to the respective MAC limits.

- Particulate filtering: HEPA filters as policing filters for filtering extremely fine aerosols.

- Activated carbon filtering: Gas adsorption on activated carbon to remove solvent residues from the air stream and minimise odour pollution.

- Energy efficiency as a cost saver: The intelligent flow control reduces the energy consumption of the suction blower and therefore sustainably saves running costs.

- Intelligent control: The extraction and filtering unit communicates directly with the laser via the integrated interface for trouble-free extraction.

- Space-saving behind the scenes: The compact design allows the extraction and filtering unit to be operated without disturbing the process.