Use case

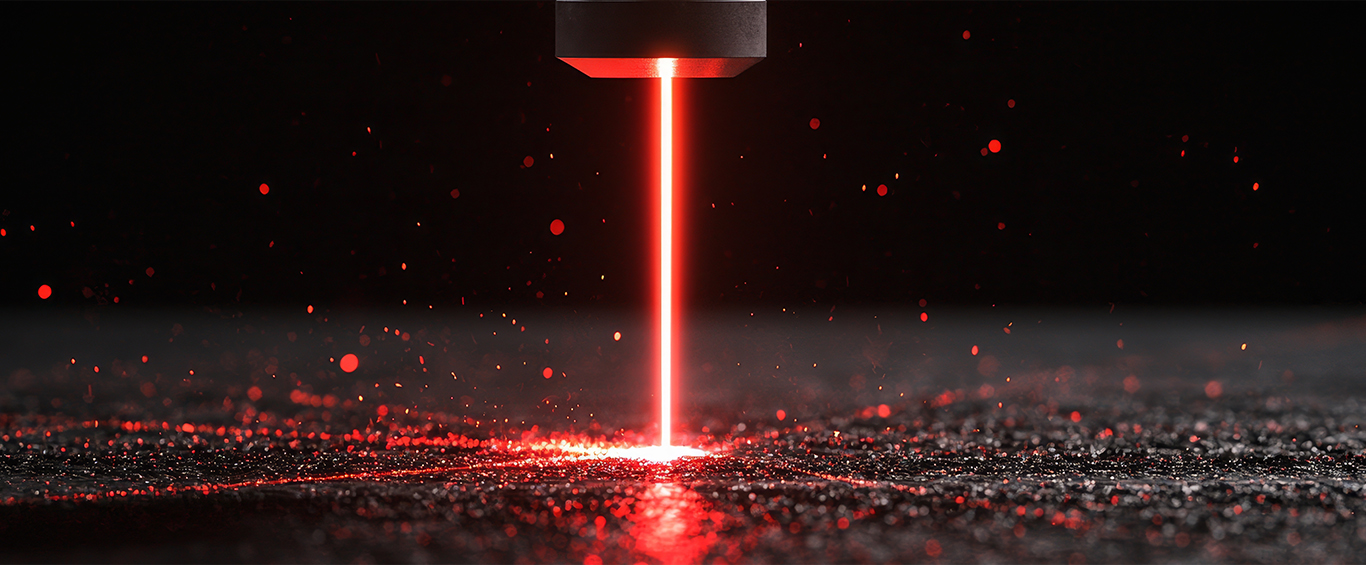

Extraction of laser emissions

Extraction of laser emissions

Perfect extraction and filtering units for marking lasers – optimum safety for users and equipment

Our engineers – on board from the very start

A leading manufacturer of laser protection booths for marking lasers contacted Fuchs Umwelttechnik:

Particles and gaseous emissions occur during lasering in the booth which are harmful both to the health of the user and to the sensitive system technology. The customer therefore wishes to offer a top-class complete package ex-factory for the extraction and filtering of the laser pollutants. This solution is also to be implemented efficiently, space-savingly and without disturbing the work process.

The initial situation:

The marking laser works inside a laser protection booth which is protected by a safety door. The closed system prevents emissions from escaping during operation. The booth is available in different sizes.

The task:

Dissolved particles gradually contaminate the inside of the booth and the high-quality laser optic.

As soon as the safety door is opened at the end of the program, the pollutants can escape unhindered into the ambient air – with all the associated health risks.

As soon as the safety door is opened at the end of the program, the pollutants can escape unhindered into the ambient air – with all the associated health risks.

- The emissions gradually contaminate the laser optic and technical equipment.

- The gases and particles that occur can escape and be inhaled when opening.

Competent expert consulting:

The customer's first contact is already with the engineers of Fuchs Umwelttechnik. The focus here is on sound advice which takes all specific conditions and requirements into consideration. The experts from Fuchs Umwelttechnik conduct an analysis and develop the requirement specification for the optimum extraction and filtering unit together with the customer.

- In order to find the best solution to the problem, the first talks take place directly between the customer and a specialist engineer from Fuchs Umwelttechnik.

- The analysis of the customer's requirements as well as the existing working and space conditions are important prerequisites for the tailor-made extraction system and exactly the right filtering unit.

The solution:

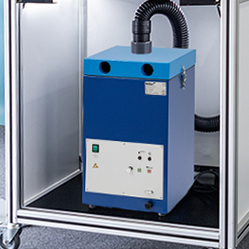

Based on the information acquired from the customer, the engineers from Fuchs Umwelttechnik design the perfectly adapted extraction and filtering unit: Specifically aimed at the laser protection booth, the specially adapted capture, the efficient transport and the corresponding extraction and filtering unit integrate smoothly into the existing system and guarantee maximum safety.

In detail:

- Complete capture: Integrated into the enclosure, the special extraction nozzle captures all laser emissions directly at their source.

- Efficient transport: The pollutants flow on unhindered to the external filtering unit through the flexible extraction hose.

- Maximum filtering: The extraction and filtering unit is adapted in its filtering and performance exactly to the laser class and the quantity and type of pollutants (flue gases and micro-particles of filter class H14 with a separation factor of 99.995 % in accordance with DIN EN1822).

- Energy efficiency as a cost saver: The intelligent flow control reduces the energy consumption of the suction blower and therefore sustainably saves running costs.

- Intelligent control: The extraction and filtering unit communicates directly with the laser via the integrated interface for trouble-free extraction.

- Space-saving behind the scenes: The compact design allows the extraction and filtering unit to be placed on or underneath the workbench without disturbing the process.

The result:

Fuchs Umwelttechnik supplies the made-to-measure extraction and filtering unit solution with technical competence and customer orientation. This gives the manufacturer of these laser protection booths the decisive lead: With this high-quality equipment, their customers not only get the safety of clean breathing air but also the advantage of a long service life of the used equipment. In addition, the energy-efficient concept of the extraction and filtering units ensures sustainable and economical operations.

Fuchs Umwelttechnik also has the right extraction and filtering solution and the tailor-made extraction and filtering unit for other laser applications such as laser cutting, laser welding, laser activation, laser marking, laser engraving or laser cleaning.

Fuchs Umwelttechnik also has the right extraction and filtering solution and the tailor-made extraction and filtering unit for other laser applications such as laser cutting, laser welding, laser activation, laser marking, laser engraving or laser cleaning.