Perfect for coarser particles – our pre-separator

Effective pollutant extraction with particle and spark separation systems – maximum safety and longer filter service life

Engineering already begins with the first customer talks

In addition to the fine particle emissions, these production areas also create coarse particles as well as inflammable dusts which can both disturb trouble-free operation of the plants and impair workplace safety.

To rule out these risks, the company needs an effective solution for suitable extraction and filtering. The measure should integrate efficient, space-savingly and seamlessly into the existing production process.

The initial situation

- For the welding of copper wires, their protective coating must be removed by a laser. This can split the protective coating into coarse particles.

Emissions with flying sparks and high combustion factors can then occur during subsequent welding. - Uniform shortening of the copper wires leads to up to 5 x 5 mm large metal residues.

- When films as part of the battery cells are cut to the right shape, the resulting film scraps are left over as waste.

The task

Without suitable technical measures, these three processes, due to the larger particle dimensions, will impair the permanent functionality of the production plants, the life of the filter systems, the cleanliness of the working environment and the health of the staff at their workplaces. In addition, there is a threat of fire from flying sparks and emissions with high combustion factors which are not self-extinguishing. The measures must work efficiently, space-savingly and without disturbing the work process.

- Coarser particle emissions of different work processes should be collected and safely extracted from the air stream.

- The particles consist of different materials (protective varnishes, copper, films).

- Spark-intensive laser welding processes demand a system which safely rules out fire risks from the air stream.

- Premature saturation of the filter elements by coarse particles must be prevented without reducing the filter service life.

- Guarantee of maximum operating safety and process stability by trouble-free integration of the technical measures in the production process.

- Easy, contamination-free handling of the separated materials.

Competent expert consulting

- In order to find the best particle and spark pre-separation, the first talks take place directly between the customer and a specialist engineer from Fuchs Umwelttechnik.

- The analysis of the customer's requirements as well as the existing working and space conditions are important prerequisites for the tailor-made extraction system and exactly the right filtering unit.

- All dust-relevant data as well as all application parameters are communicated to define the remaining risks.

- For a highly efficient extraction process, adapted precisely to the volumes of dust that occur, all parameters of the extraction and filtering system must be planned and designed exactly.

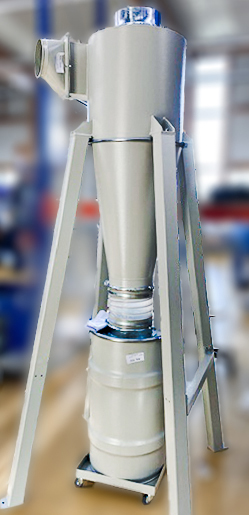

The solution

In detail:

- Pre-separation of coarse particles: Gravity separators separate heavy particles in advance.

- Spark separation: Special quenching modules reliably prevent embers from entering the filtering system.

- Long filter life: Since only fine particles can get into the filters of the extraction and filtering unit, these are able to maintain their high separation factor for longer.

- Safe disposal: Coarse emissions are collected in steel drums with or without polythene bags.

- Individual special solutions: Special systems for larger waste parts such as wire ends or film scraps.

- Technical consulting: Direct communication with a Fuchs engineering specialist for optimum adaptation to every application.

The result:

- Greatly enhanced work safety due to effective spark and particle separation,

- Longer filter lives thanks to a reduced load on the filters,

- Cost efficiency due to less maintenance expense,

- Sustainable protection of users and plants.

We also design pre-separation systems for oil mist pre-separation or for separation of coarser particle in chip production for the laser singling of chips. Fuchs Umwelttechnik always supplies the best extraction and filtering solution and the tailor-made extraction and filtering unit.